Why Nickel Alloys? The Ultimate Material Solution

Nickel alloys are the superheroes of the metal world. They offer a unique combination of properties unmatched by standard stainless steels:

Extreme Corrosion Resistance: Unrivaled performance in acids, alkalis, and chloride-rich environments.

High-Temperature Strength: Maintain integrity and mechanical properties from cryogenic ranges up to 1200°C+.

Oxidation & Carburization Resistance: Excellent for furnace and heat-treating applications.

Toughness in Cryogenic Service: Remain ductile and reliable at ultra-low temperatures.

Specialized Properties: Tailored for specific threats like sulfuric acid, seawater, or sour gas (H₂S).

Our Nickel Alloy Portfolio: A Material for Every Challenge

BENKOO METAL stocks and supplies a comprehensive range of nickel alloy grades. Find your perfect match below.

Popular & High-Temperature Alloys

Alloy Group | Common Trade Name | UNS Number | Key Features & Composition | Ideal For |

Nickel-Chromium | Inconel® 600 | N06600 | Excellent oxidation resistance, good strength up to 1175°C. (72%Ni, 15%Cr) | Furnace components, chemical processing, thermal processing equipment. |

Nickel-Chromium-Iron | Inconel® 601 | N06601 | Superior oxidation resistance & high mechanical strength. Excellent for cyclic heating. | Radiant tubes, heat treatment fixtures, aerospace combustion parts. |

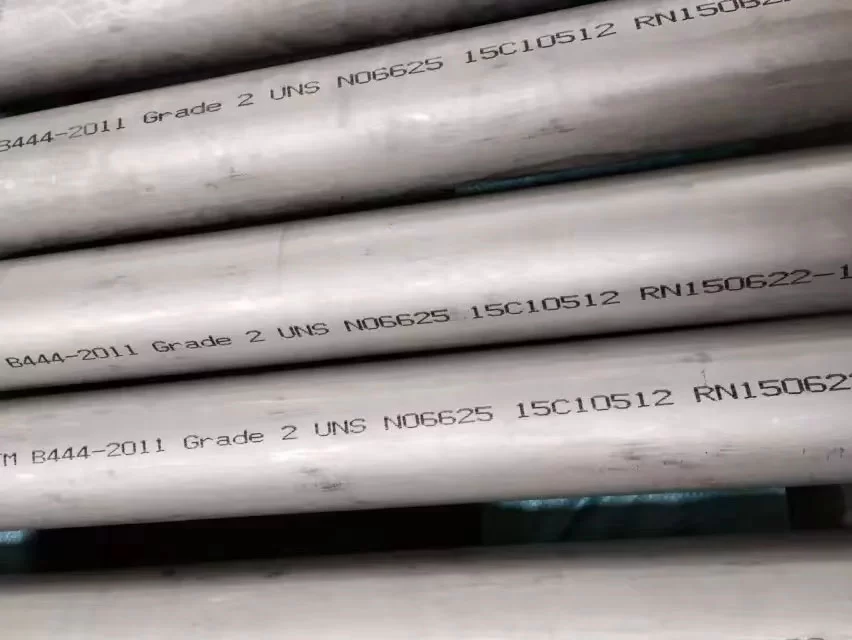

Nickel-Chromium-Mo | Inconel® 625 | N06625 | Exceptional fatigue & thermal fatigue strength. High corrosion resistance from Mo & Nb. (61%Ni, 21.5%Cr, 9%Mo) | Marine engineering, aerospace, chemical processing, seawater applications. |

Nickel-Chromium-Iron | Inconel® 718 | N07718 | Age-hardenable, superb strength up to 700°C. Excellent weldability. | Jet engine components, gas turbines, high-strength fasteners. |

Iron-Nickel-Chromium | Incoloy® 800H/HT | N08810/N08811 | Optimized for high-temperature service. Excellent strength, oxidation, and carburization resistance. | Heat exchanger tubing, reformer and pyrolysis furnace tubes, power generation. |

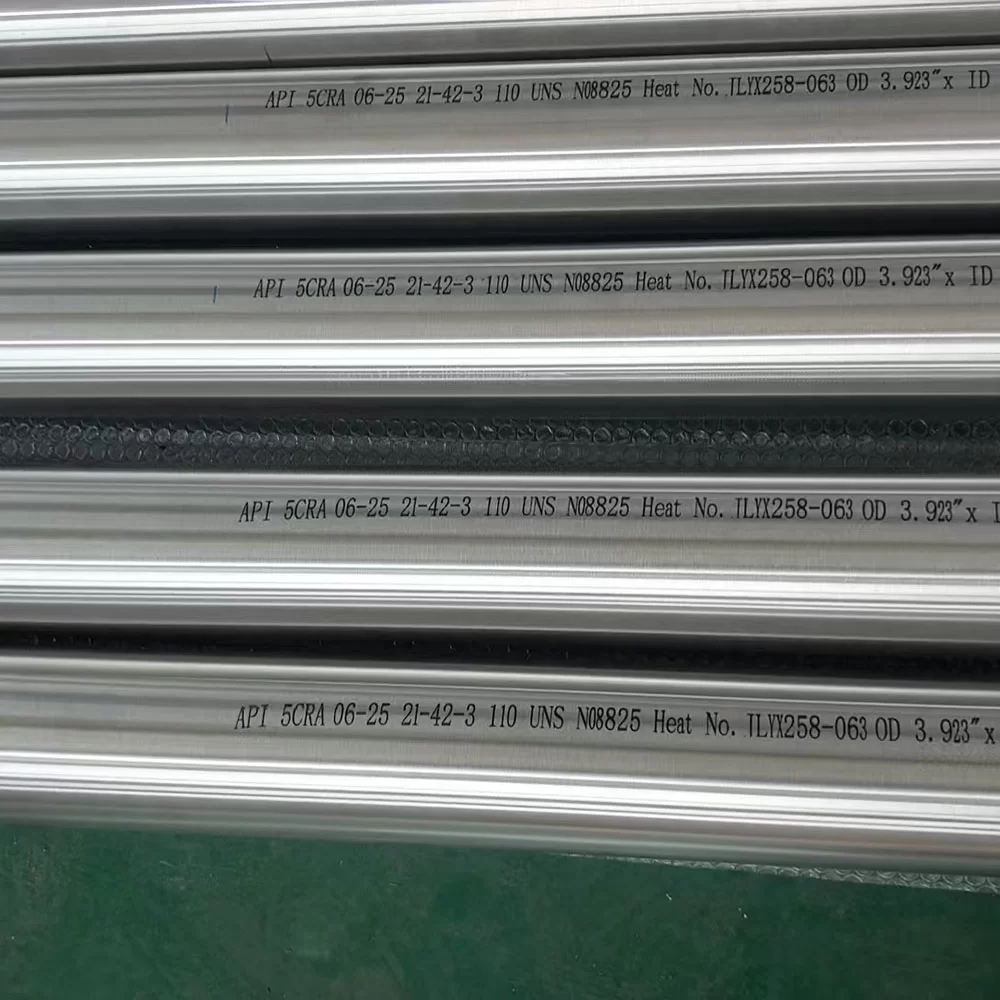

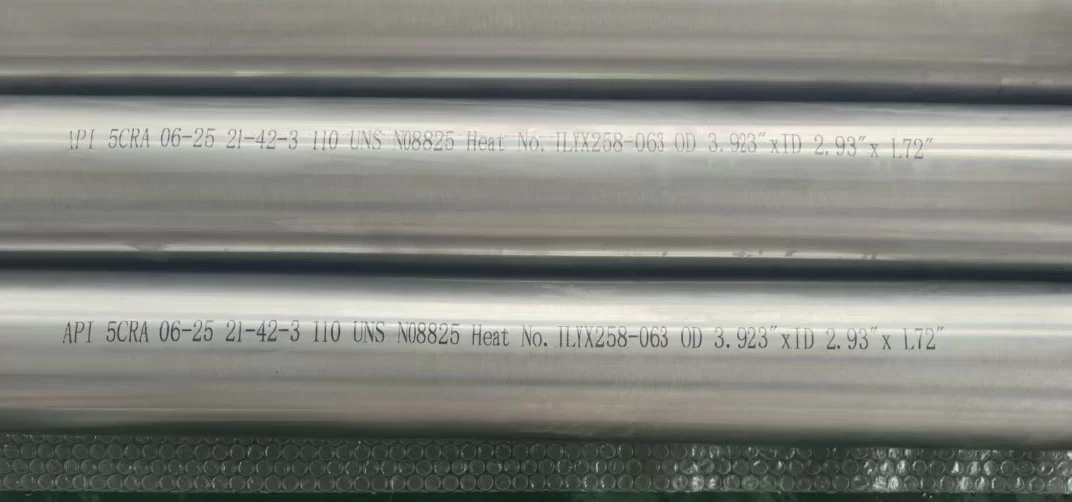

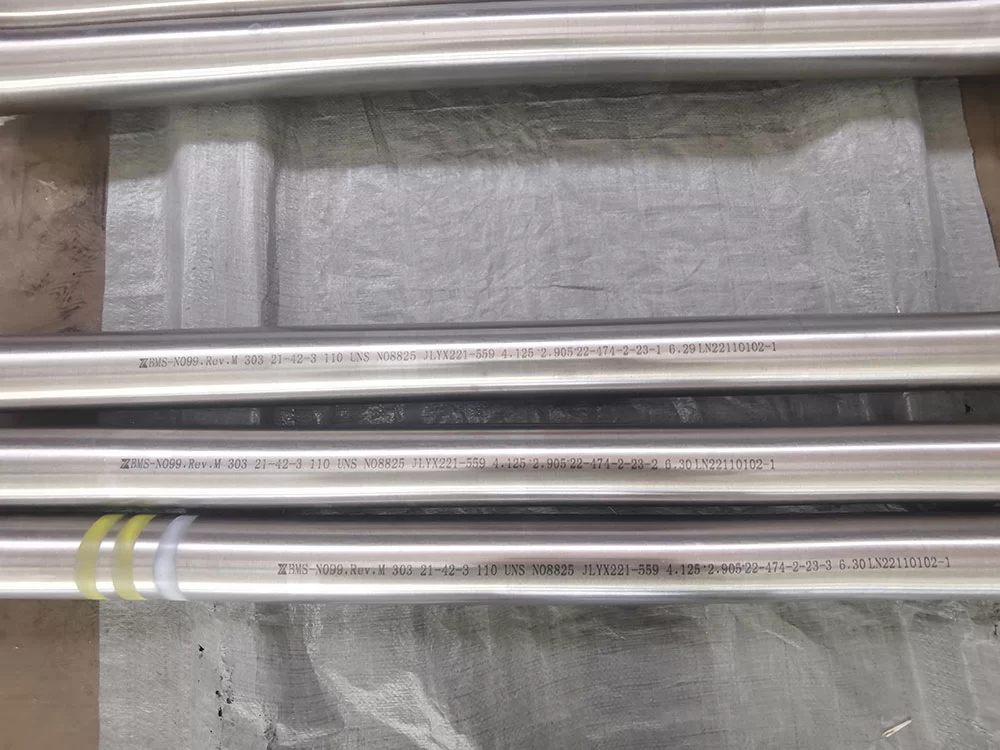

Iron-Nickel-Chromium | Incoloy® 825 | N08825 | Excellent resistance to reducing and oxidizing acids. Good stress corrosion cracking resistance. | Sulfuric and phosphoric acid pickling tanks, offshore oil & gas piping. |

Champion Corrosion Fighters

Alloy Group | Common Trade Name | UNS Number | Key Features & Composition | Ideal For |

Nickel-Molybdenum | Hastelloy® B-2 | N10665 | Unparalleled resistance to hydrochloric acid and other reducing agents. Low carbon. | HCl production and handling, chemical reactors. |

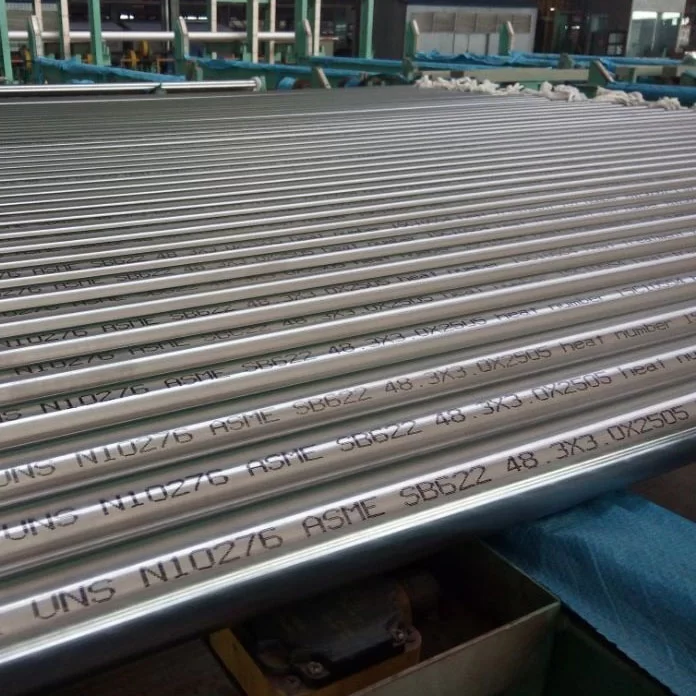

Nickel-Molybdenum-Chromium | Hastelloy® C-276 | N10276 | The "workhorse" for severe corrosion. Resists pitting, crevice corrosion, and oxidizing chlorides. | Pollution control (FGD), pulp & paper bleach plants, aggressive chemical reactors. |

Nickel-Molybdenum-Chromium | Hastelloy® C-22® | N06022 | Even broader corrosion resistance than C-276, especially in mixed acid/oxidizing environments. | Chemical process industry, pharmaceutical, waste treatment. |

Nickel-Copper | Monel® 400 | N04400 | Excellent resistance to seawater and fast-flowing brackish water. High strength. (67%Ni, 30%Cu) | Marine engineering, chemical processing vessels, seawater cooling systems. |

Age-Hardenable Ni-Cu | Monel® K-500 | N05500 | Same corrosion resistance as Monel 400 but with higher strength via age-hardening. | Pump shafts, marine propeller shafts, oil drill tools. |

Nickel-Iron-Chromium | Alloy 20 (Carpenter 20) | N08020 | Excellent resistance to sulfuric acid and chloride stress corrosion cracking. Added Cu & Mo. | Sulfuric acid plants, chemical processing, food processing equipment. |

Global Standards & Quality Assurance

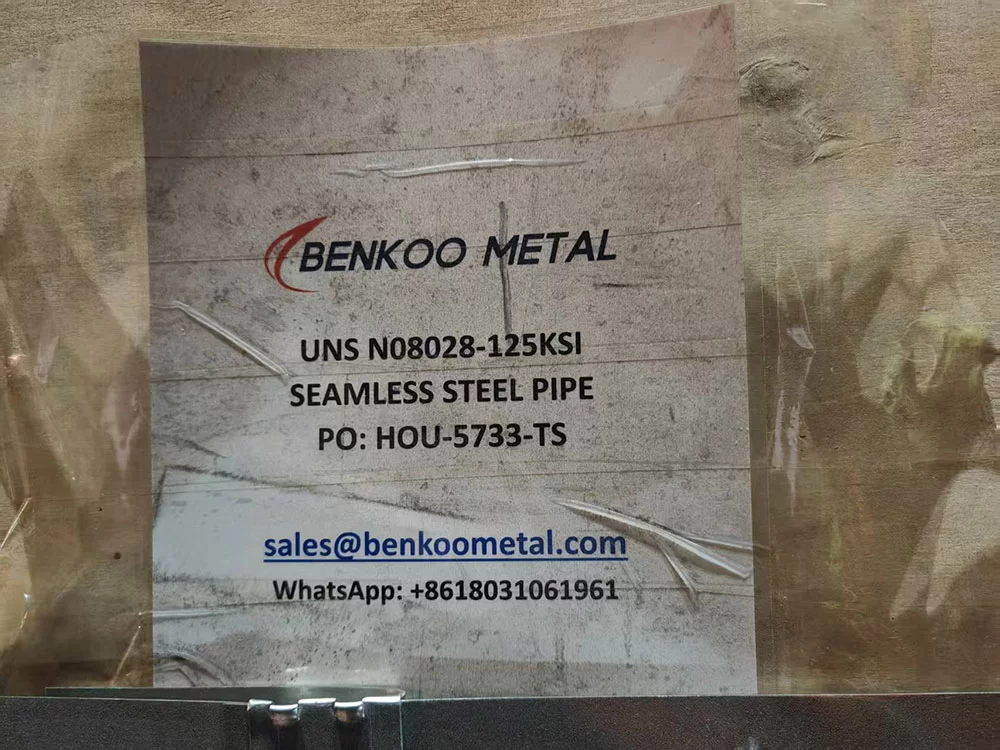

Every BENKOO METAL nickel alloy pipe is produced and certified to meet the world's most rigorous standards.

Primary Product Standards

Region | Standard Number | Title / Scope |

USA (ASTM/ASME) | ASTM B161 / B167 / B829 | Standard Specification for Nickel Seamless Pipe & Tube / General Requirements. |

| ASTM B444 / B622 / B619 | Specifications for Nickel-Chromium-Molybdenum-Columbium Alloys (625), Nickel-Cobalt Alloys, Welded Pipe. |

| ASME SB-XXX | Boiler and Pressure Vessel Code equivalents. |

Europe (EN) | EN 10216-5 | Seamless steel tubes for pressure purposes – Part 5: Stainless steel tubes (includes Ni alloys). |

| EN 10095 | Heat resisting steels and nickel alloys. |

Germany (DIN) | DIN 17750 | Seamless circular tubes of nickel and nickel alloys – Technical delivery conditions. |

Japan (JIS) | JIS H4551 | Nickel and nickel alloy seamless pipes and tubes. |

| JIS H4553 | Heat-resistant nickel alloy seamless pipes and tubes. |

International | ISO 6207 | Nickel and nickel alloys — Seamless pipe and tube. |

Industry-Specific | NACE MR0175/ISO 15156 | Materials for use in H₂S-containing environments in oil and gas production. |

| API 5LC | Specification for CRA (Corrosion Resistant Alloy) Line Pipe. |

Our Stringent Testing Protocol

Chemical Analysis: Verified to ASTM E1473 / EN 10204 3.1/3.2.

Mechanical Testing: Tensile, yield, elongation per ASTM A370 / ISO 6892-1.

Non-Destructive Testing (NDT): 100% Ultrasonic (ASTM E213) or Eddy Current testing.

Hydrostatic Testing: Per ASTM B829 / ISO 3458.

PMI (Positive Material Identification): XRF analyzer verification.

Intergranular Corrosion Test: ASTM G28 Method A for critical alloys.

Full Traceability: From melt heat number to final product.

Where BENKOO METAL Nickel Alloys Excel

Industry | Critical Applications | Recommended Alloys |

Chemical & Petrochemical | Reactors, columns, heat exchangers, piping for sulfuric, hydrochloric, phosphoric acid. Downhole tubing for sour (H₂S) service. | Hastelloy C-276, C-22, B-2; Inconel 625; Alloy 20 |

Aerospace & Gas Turbines | Jet engine combustion chambers, exhaust ducts, turbine seals, afterburner parts. | Inconel 600, 601, 625, 718; Hastelloy X |

Power Generation | Superheater/reheater tubing, boiler components in advanced ultra-supercritical (A-USC) plants, nuclear reactor control rod tubing. | Inconel 617, 740H; Incoloy 800H/HT |

Marine & Offshore | Seawater cooling systems, propeller shafts, pump components, subsea umbilicals, ballast water systems. | Monel 400/K-500; Inconel 625; Alloy 825 |

Oil & Gas (Upstream) | Downhole instrumentation housings, high-pressure high-temperature (HPHT) well components, choke and kill lines. | Inconel 725, 925; Alloy 718; Duplex/Super Duplex for specific zones |

The BENKOO METAL Difference: More Than a Supplier

Choosing BENKOO METAL means choosing a dedicated technical partner.

Expert Material Selection: Our engineers help you select the most cost-effective alloy for your specific service environment.

Precision Manufacturing: We supply pipes with superior surface finish and tight dimensional tolerances, ready for your fabrication.

Global Logistics Network: Reliable and timely delivery to your job site or fabricator, anywhere in the world.

Technical Documentation: Comprehensive Mill Test Certificates (MTCs), material traceability, and compliance documentation provided seamlessly.

Your Partner in Performance: We are invested in the success and longevity of your project.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

-20251219035019.webp)

-20251219064452.webp)

-20251219053336.webp)

-20251219063146.webp)