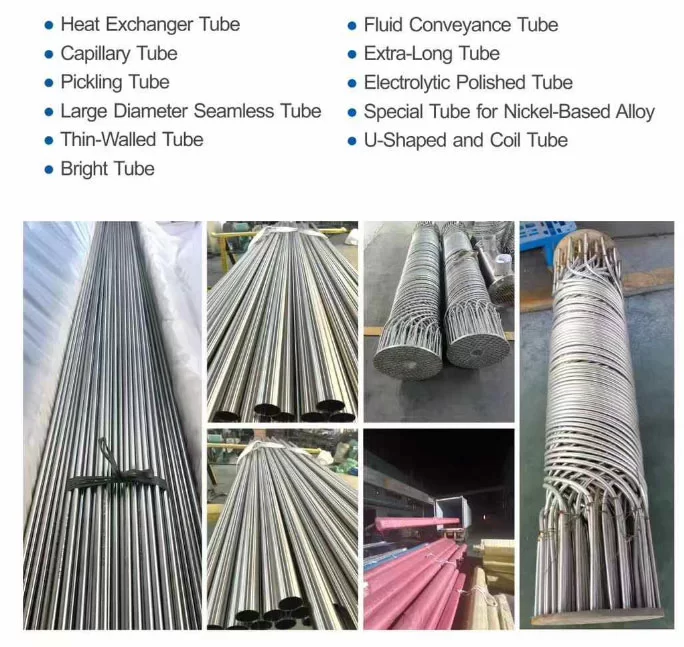

PRODUCT INTRODUCTION: DUPLEX & SUPER DUPLEX STAINLESS STEELS

Duplex Stainless Steels are a family of steels with a mixed microstructure of approximately 50% austenite and 50% ferrite. This unique structure combines the most desirable properties of both phases:

From Austenite: Excellent toughness and corrosion resistance.

From Ferrite: High strength and resistance to stress corrosion cracking.

Super Duplex grades contain higher alloying contents (Chromium, Molybdenum, Nitrogen) for even greater performance, particularly defined by a Pitting Resistance Equivalent Number (PREN = %Cr + 3.3x%Mo + 16x%N) typically exceeding 40.

Key Advantages of BENKOO METAL Duplex & Super Duplex Pipes:

High Strength: Yield strength is approximately double that of standard austenitic grades (304, 316), allowing for reduced wall thickness and weight savings.

Excellent Corrosion Resistance: Superior resistance to chloride-induced stress corrosion cracking (SCC), pitting, and crevice corrosion.

Cost Efficiency: Higher strength-to-weight ratio often provides a more cost-effective solution than highly alloyed austenitics.

Good Weldability: With proper procedures, they can be welded using common techniques.

MATERIAL SPECIFICATIONS & GRADES

BENKOO METAL offers a comprehensive range of Duplex and Super Duplex stainless steel grades, tailored for varying levels of corrosive severity and mechanical demand.

Duplex Stainless Steel Grades

Common Name | UNS Number | EN Designation | PREN (Typical) | Key Characteristics & Typical Composition | Primary Applications |

Lean Duplex (e.g., 2304) | S32304 | 1.4362 | 25-27 | Lower alloy, cost-effective. 23% Cr, 4% Ni, 0.1% N. Good alternative to 316L where higher strength is needed. | Water treatment, tanks, structural components in mildly corrosive atmospheres. |

Standard Duplex (2205) | S31803 / S32205 | 1.4462 | 34-38 | The workhorse grade. 22% Cr, 5% Ni, 3% Mo, 0.17% N. Excellent all-round corrosion resistance & strength. | Chemical tankers, heat exchangers, pulp & paper industry, oil & gas process piping. |

High-Alloy Duplex | S32506 / S32550 | 1.4507 / 1.4506 | 38-41 | Higher Mo & N than 2205. 25% Cr, 6-7% Ni, 3-4% Mo. Better corrosion resistance, especially in hot chloride solutions. | Offshore oil & gas, seawater cooling, FGD systems. |

Super Duplex Stainless Steel Grades

Common Name | UNS Number | EN Designation | PREN (Typical) | Key Characteristics & Typical Composition | Primary Applications |

2507 (Standard Super) | S32750 | 1.4410 | 42-45 | 25% Cr, 7% Ni, 4% Mo, 0.27% N. The benchmark for Super Duplex performance. | Seawater systems, offshore umbilicals, high-pressure oil & gas wells, desalination plants. |

Zeron® 100 / 2707 | S32760 | 1.4501 | 40-42 | 25% Cr, 7% Ni, 3.6% Mo, 0.7% W, 0.24% N. Tungsten addition enhances corrosion resistance in reducing acids. | Chemical process industry, aggressive offshore environments, seawater handling. |

UR 52N+® | S32520 | 1.4507 | 38-42 | 25% Cr, 6.5% Ni, 3.5% Mo, 0.5% Cu, 0.23% N. Excellent resistance to sour environments (H₂S). | Oil & gas production (sour service), geothermal wells. |

Hyper-Duplex (e.g., 3207 HD) | S33207 | 1.4655 | ≥49 | 27% Cr, 6.5% Ni, 4.8% Mo, 0.4% N. The highest corrosion resistance class, surpassing many nickel alloys in specific media. | Extreme offshore conditions, concentrated chloride solutions, aggressive chemical processing. |

Japanese Standard (JIS) Grades

While JIS standards traditionally focused more on austenitics, equivalent grades are supplied based on chemical composition matching to UNS/EN standards (e.g., material matching SUS 329J3L for 2205). BENKOO METAL provides full traceability and certification to ensure our duplex products meet the required specifications for projects following Japanese standards.

INTERNATIONAL STANDARDS COMPLIANCE

BENKOO METAL pipes are produced and certified to meet the most stringent global standards for seamless ferritic/austenitic duplex pipes.

Primary Product & Material Standards

Standard System | Standard Number | Title / Scope |

American (ASTM/ASME) | ASTM A790/A790M | Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe |

| ASTM A789/A789M | Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service |

| ASME SA789 / SA790 | ASME Boiler and Pressure Vessel Code versions. |

European (EN) | EN 10216-5 | Seamless steel tubes for pressure purposes – Part 5: Stainless steel tubes (includes duplex grades). |

| EN 10088-3 | Technical delivery conditions for sheets/plates and strips for corrosion resisting steels. |

German (DIN) | DIN 17456 | Seamless circular stainless steel tubes – Technical delivery conditions. |

International (ISO) | ISO 17781 | Petroleum, petrochemical and natural gas industries — Test methods for quality control of microstructure of ferritic/austenitic (duplex) stainless steels. |

Norwegian (NORSOK) | MDS D63 / M-630 | Material Data Sheets for Duplex Stainless Steels – Required for many North Sea offshore projects. |

Japanese (JIS) | JIS G3459 (Referenced) | Stainless steel pipes for ordinary piping. Chemical composition equivalents supplied. |

| JIS G3463 (Referenced) | Stainless steel pipes for boiler and heat exchanger. |

Supplementary & Testing Standards

Chemical Analysis: ASTM A751, EN 10204 3.1/3.2

Mechanical Testing: ASTM A370, ISO 6892-1

Pitting Corrosion Test: ASTM G48 Methods A, C, & E (Critical Pitting Temperature – CPT)

Phase Balance (Ferrite/Austenite): ASTM E562, ISO 8249

Intergranular Corrosion: ASTM A262 Practice E (Streicher Test) or Practice C (Huey Test for higher alloys)

Hardness Testing: ASTM E10/E18, ISO 6506/6507/6508

Non-Destructive Testing (NDT): ASTM E213 (Ultrasonic), ASTM E709 (Magnetic Particle), EN 10246 series

Hydrostatic Testing: ASTM A999, ISO 3458

APPLICATIONS OF BENKOO METAL DUPLEX & SUPER DUPLEX PIPES

Our pipes are engineered for critical infrastructure where failure is not an option.

Industry Sector | Specific Applications | Why Duplex/Super Duplex? | Recommended BENKOO METAL Grades |

Oil & Gas (Upstream/Midstream) | Subsea flowlines & risers, topside process piping, seawater injection lines, hydraulic lines, Christmas tree components. | Resistance to chloride SCC & pitting in seawater/brine, high strength reduces wall thickness, good weldability for fabrication. | 2205, 2507, S32760 |

Chemical & Petrochemical | Reactor effluent air coolers, heat exchanger tubing, piping for acidic/chloride-containing process streams, pressure vessels. | Superior resistance to a wide range of acids (sulfuric, phosphoric) and chloride environments compared to 316L. | 2205, S32520, S32760 |

Pulp & Paper | Digester circulator lines, bleach plant washers & piping, black liquor recovery systems. | Outstanding resistance to chloride-containing liquors and stress corrosion cracking. | 2205, 2507 |

Desalination & Water Treatment | High-pressure RO membranes piping, brine heater tubes, seawater intake lines, evaporator tubes in MED/MSF plants. | Unmatched resistance to pitting and crevice corrosion in hot, chloride-concentrated seawater. | 2507, S32760, Hyper-Duplex |

Marine & Offshore | Seawater cooling systems, ballast piping, firewater systems, hydraulic systems on vessels & platforms. | High strength for weight-sensitive designs, excellent resistance to marine biofouling and corrosion. | 2205, 2507 |

Pollution Control (FGD) | Ducting, dampers, chimney liners, absorber towers in flue gas desulfurization units. | Resists condensation of chlorides and acidic compounds at elevated temperatures. | 2205, 2507 |

Chemical Tankers | Cargo pipelines, tanks, and unloading systems. | High strength allows for thinner, lighter tanks (increased payload), excellent corrosion resistance to various chemicals. | 2205, 2507 |

THE BENKOO METAL ADVANTAGE

Choosing BENKOO METAL for your Duplex and Super Duplex requirements means partnering with a specialist focused on metallurgical excellence and application success.

Metallurgical Precision: Strict control over chemical composition, heat treatment, and phase balance (target 40-60% ferrite) to ensure optimal properties.

Comprehensive Certification: We supply full material traceability with EN 10204 3.2 certificates, including mill test reports for chemistry, mechanical properties, and results of specific corrosion tests (CPT per ASTM G48).

Technical Partnership: Our engineers provide support on material selection, weld procedure qualification (WPQ), and application engineering to ensure your project's integrity.

Global Standard Mastery: Expertise in meeting and certifying to ASTM, EN, NORSOK, and other project-specific standards worldwide.

Reliable, Consistent Supply: Robust manufacturing and quality processes ensure on-time delivery of products that perform as specified, batch after batch.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

-20251219063146.webp)

-20251219035019.webp)