The semiconductor industry utilizes a variety of alloys beyond the common 304/316L stainless steels to address unique challenges in corrosion resistance, high-temperature stability, and ionic contamination control. BENKOO METAL’s expertise lies in supplying and processing this full spectrum of materials.

The table below expands on the material portfolio, detailing their characteristics and primary applications within semiconductor manufacturing.

Material Category | Typical Grades / UNS Numbers | Key Characteristics & Metallurgy | Primary Semiconductor Fab Applications |

Austenitic Stainless Steels (Standard) | 304/L (S30400/S30403), 316L (S31603), 316LVM (Vacuum Melted) | Excellent general corrosion resistance, good formability/weldability. Low carbon “L” grades resist sensitization. Vacuum melting enhances purity. | General service lines, non-critical gas delivery, outer jackets, structural components. 316L is the baseline for most high-purity gas systems. |

Austenitic Stainless Steels (Advanced) | 904L (N08904), 6% Molybdenum Grades (e.g., S31254, AL-6XN®/N08367) | Very high resistance to pitting & crevice corrosion (high PREN). Superior performance in halide (chloride, fluoride) environments. | Ultra-pure water (UPW) systems, chemical mechanical planarization (CMP) slurry lines, aggressive acidic/alkaline wet bench chemistries. |

Ferritic Stainless Steels | 444 (S44400), 446 (S44600) | Good chloride stress corrosion cracking (SCC) resistance and thermal conductivity. Magnetic. | Applications with cooling water or environments prone to chloride-induced SCC where austenitics may fail. |

Duplex Stainless Steels | 2205 (S32205/S31803) | Mixed austenite-ferrite structure. High strength (~2x 316L), excellent chloride SCC resistance. | Structural supports, bracketry, and utility lines in fab areas where strength and corrosion resistance are both critical. |

Nickel-Based Alloys | Alloy C-276 (N10276), Alloy 625 (N06625), Alloy 600 (N06600) | Exceptional resistance to a wide range of severely corrosive oxidizing and reducing chemicals. Maintain strength at high temperatures. | Extreme service: furnace tubes (diffusion, LPCVD), epitaxy chambers, components handling strong acids (HF, HCl, H₂SO₄) or plasma effluents. |

Specialty & Precision Alloys | Titanium Gr. 2 (R50400), Titanium-Palladium Alloys, Nickel 200/201 (N02200/N02201) | Titanium: Outstanding corrosion resistance, lightweight, compatible with ultra-aggressive chemicals. | Titanium: Chambers and lines for ultra-aggressive chemistries (e.g., concentrated HCl, chlorine). |

BENKOO METAL's Application-Centric Approach & Key Advantages

Selecting the correct material is fundamental to system longevity and process integrity. BENKOO METAL’s engineers work with clients to match the alloy to the specific chemical, thermal, and purity challenges of the application, ensuring cost-effective and reliable performance.

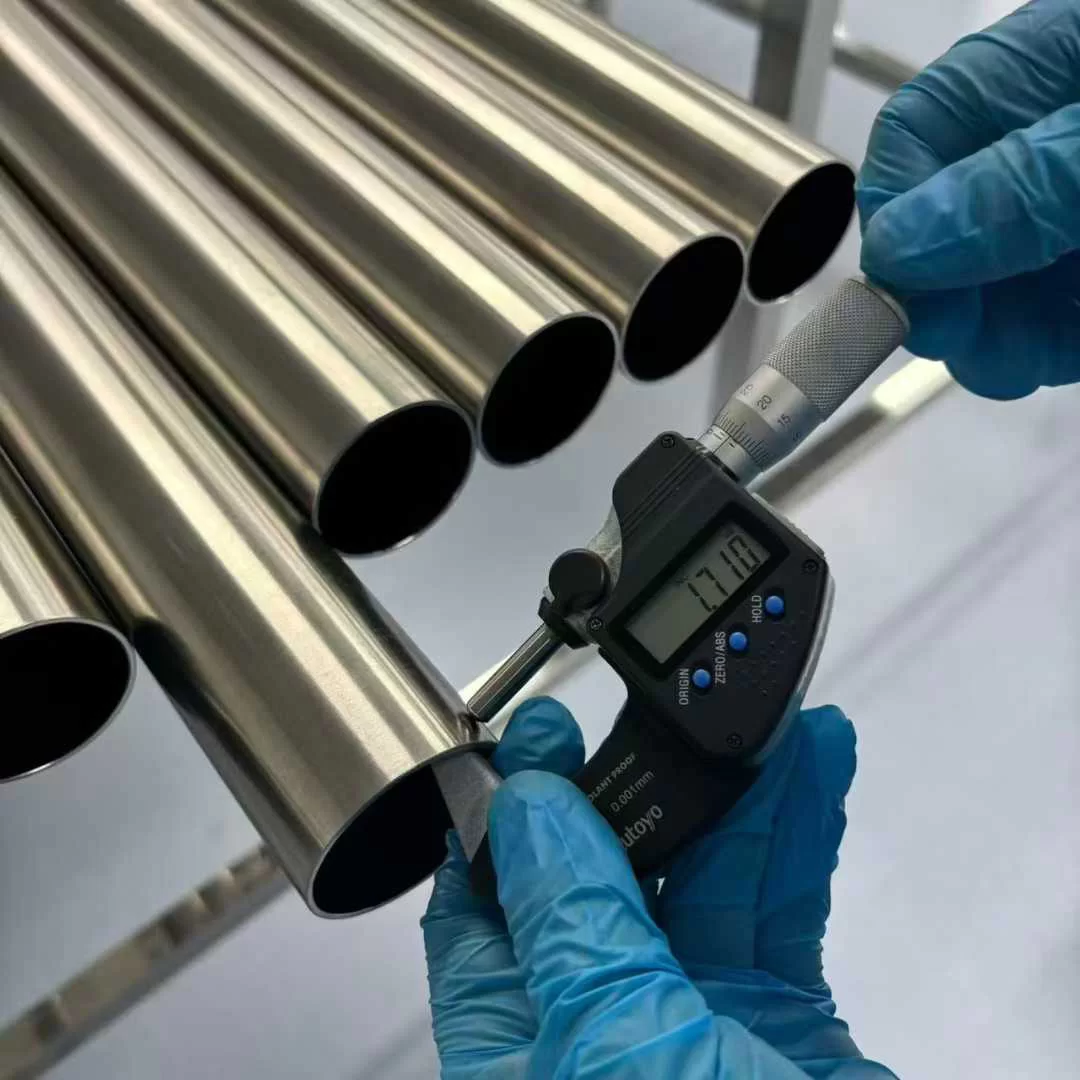

Quality and Consistency Across All Alloys: Whether supplying standard 316L or sophisticated nickel alloys, BENKOO METAL enforces the same rigorous quality protocol. We ensure precise chemical composition, dimensional tolerances, and—for critical applications—provide Electro-Polished (EP) or Mechanically Polished (MP) finishes with verified low surface roughness and particle counts.

Reliable Supply and Fast Delivery for Specialty Materials: We maintain strategic partnerships with premium mills and manage controlled inventory of key semiconductor-grade alloys. This allows BENKOO METAL to offer predictable lead times and stable supply even for less common materials, mitigating project risks and keeping your fab expansion or tool installation schedules on track.

Full Documentation and Traceability: All materials are supplied with complete Mill Test Certificates (MTC) and material traceability (Heat Number). For EP/MP tubes, additional certification including surface roughness (Ra) reports and cleanroom packaging records are provided, supporting your quality assurance and audit requirements.

Contact BENKOO METAL to consult with our technical specialists. We will help you identify the optimal material and specification from our comprehensive portfolio for your specific semiconductor gas, chemical, or process system application.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

-20251219092442.webp)

-20251219054209.webp)

-20251219055937.webp)