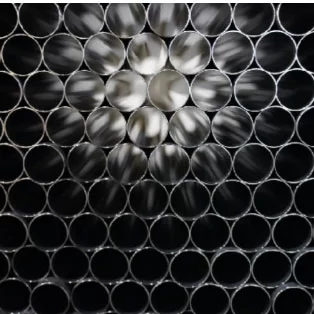

BENKOO METAL supplies a comprehensive range of seamless tubes designed to meet the rigorous specifications of thermal and pressure equipment.

Product Category Overview

Product Category | Primary Function | Key Industry Applications |

Boiler Tubes | Facilitate heat transfer from combustion gases to water/steam. | Superheater, Reheater, Economizer, Water Wall panels in power station & industrial boilers. |

Heat Exchanger Tubes | Enable thermal exchange between two separated fluids. | Shell & Tube, U-Tube, and Finned Tube heat exchangers in chemical plants, refineries, HVAC. |

Pressure Vessel Tubes | Serve as integral components (e.g., nozzles, manways, internal coils) for containing pressurized fluids. | Reactors, separators, storage tanks, and process vessels in oil & gas, petrochemical sectors. |

Technical Specifications & Material Grades

Our tubes conform to major international standards and are available in a wide range of materials.

Category | Key Standards | Common Material Grades | Typical Size Range (OD) |

Boiler Tubes | ASTM A213, ASME SA213 | Carbon Steel: SA178C/A | 12.7 mm – 127 mm (0.5" – 5") |

Heat Exchanger Tubes | ASTM A213, A269, ASME SA213, SA249 | Stainless Steel: TP304/304L, TP316/316L, TP321,TP347H | 6.35 mm – 50.8 mm (0.25" – 2") |

Pressure Vessel Tubes | ASTM A213, A335, ASME SA213, SA335 | Carbon Steel: SA106 B/C | 10 mm – 200 mm+ (Custom) |

Key Features of BENKOO METAL Tubes:

Superior Material Integrity: Seamless construction ensures uniform structure and enhanced pressure-bearing capability, free from longitudinal welds.

Precision Dimensional Control: Guaranteed tolerances on outer diameter (OD), wall thickness (WT), and ovality for optimal fit and performance in tube sheets.

Optimized for Service: Materials are selected and processed (e.g., heat treatment, finishing) to deliver specific properties like creep strength (for boilers) or corrosion resistance (for exchangers).

Full Certification: Supplied with complete Mill Test Certificates (MTC) and traceability to meet code compliance (ASME, PED).

If you have any camping barbeque equipment inquiry, please feel free to contact us.

-20251219071741.webp)