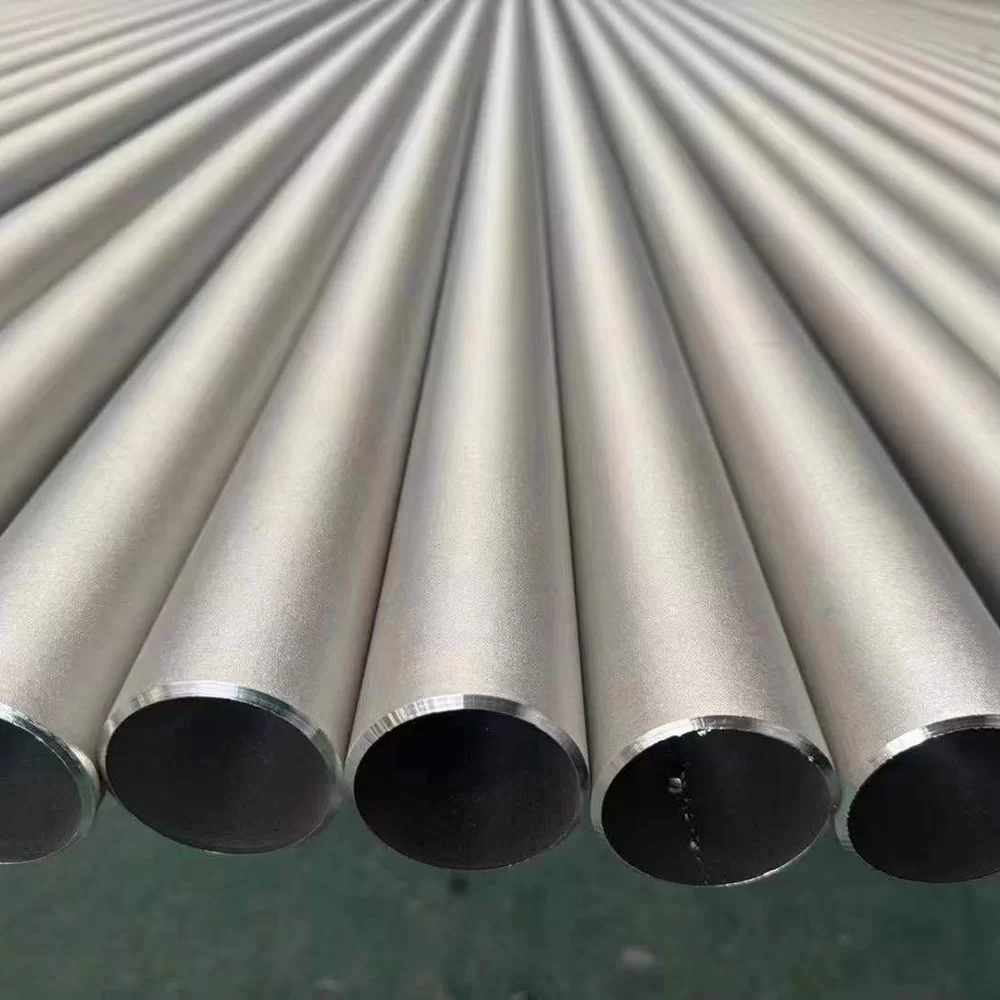

Austenitic stainless steels are the most widely used category of stainless steel, renowned for their excellent corrosion resistance, high ductility, and good mechanical properties across a wide temperature range. BENKOO METAL's seamless pipes are manufactured using state-of-the-art processes to ensure superior metallurgical structure, dimensional accuracy, and performance consistency.

Key Characteristics:

Non-Magnetic: Typically non-magnetic in the annealed condition.

Excellent Corrosion Resistance: Superior resistance to a wide range of atmospheric, chemical, and organic corrodents.

High Ductility & Toughness: Excellent formability and impact resistance, even at cryogenic temperatures.

Good Weldability: Can be welded by all standard fusion and resistance methods.

Hygienic Surface: Smooth, non-porous surface ideal for sanitary applications.

Material Specifications & Grades

BENKOO METAL offers an extensive portfolio of austenitic stainless steel grades to suit various corrosive environments and service conditions.

American Standard (ASTM/UNS) Grades

Grade (Common Name) | UNS Number | Key Characteristics & Typical Composition | Primary Applications |

304 / 304L | S30400 / S30403 | 18% Cr, 8% Ni, low carbon (L). Excellent general-purpose corrosion resistance, formability, and weldability. | Food processing equipment, chemical containers, architectural trim, household appliances. |

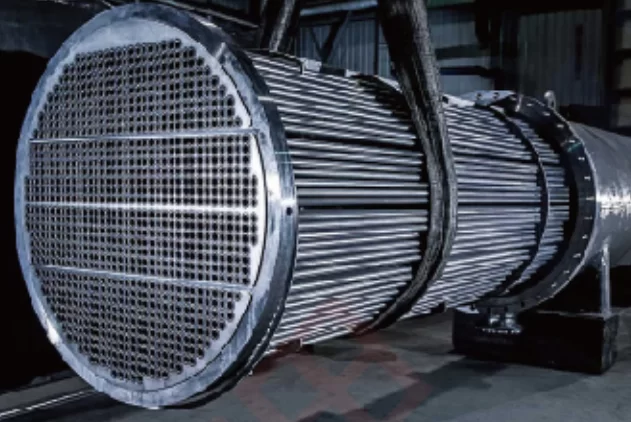

304H | S30409 | Higher carbon version of 304 for improved high-temperature strength. | High-temperature applications like heat exchangers, boiler tubes, superheaters. |

316 / 316L | S31600 / S31603 | 16-18% Cr, 10-14% Ni, 2-3% Mo. Enhanced resistance to pitting and crevice corrosion, especially from chlorides. | Marine environments, chemical processing, pharmaceutical equipment, coastal architectural facades. |

316H | S31609 | Higher carbon version of 316 for high-temperature service. | High-temperature, high-pressure chemical processes, power generation. |

317 / 317L | S31700 / S31703 | Higher Mo (~3-4%) than 316. Superior resistance to aggressive chemicals and sulfuric acid. | Pulp & paper industry, chemical processing with severe conditions. |

321 | S32100 | Stabilized with Titanium (Ti). Resists chromium carbide precipitation during welding, preventing intergranular corrosion. | Aircraft exhaust manifolds, expansion joints, furnace parts. |

347 | S34700 | Stabilized with Niobium (Nb). Similar to 321, with excellent intergranular corrosion resistance. | Welded assemblies in corrosive environments, high-temperature aircraft components. |

310 / 310S | S31000 / S31008 | High chromium (25%) and nickel (20%). Outstanding oxidation resistance at high temperatures. | Heat treating equipment, furnace components, radiant tubes. |

904L | N08904 | High-alloy austenitic (20-25% Cr, 24-26% Ni, 4-5% Mo, 1-2% Cu). Exceptional resistance to a wide range of acids, especially sulfuric. | Chemical processing, pollution control, seawater cooling, acid production. |

6Mo Super Austenitic (e.g., 254 SMO®) | S31254 | Very high Mo (6%), N addition. Extremely high resistance to pitting and crevice corrosion (PREN > 40). | Seawater desalination, offshore oil & gas, flue gas desulfurization, aggressive chemical environments. |

European Standard (EN/DIN) Grades

Material Number (EN) | Old DIN Designation | Common Name / Similar U.S. Grade | Key Features |

1.4301 | X5CrNi18-10 | AISI 304 | Standard austenitic grade, general purpose. |

1.4307 | X2CrNi18-9 | AISI 304L | Low carbon version of 1.4301, excellent weldability. |

1.4401 | X5CrNiMo17-12-2 | AISI 316 | Molybdenum-bearing for improved corrosion resistance. |

1.4404 | X2CrNiMo17-12-2 | AISI 316L | Low carbon version of 1.4401. |

1.4541 | X6CrNiTi18-10 | AISI 321 | Titanium-stabilized against intergranular corrosion. |

1.4571 | X6CrNiMoTi17-12-2 | AISI 316Ti | Titanium-stabilized molybdenum-bearing grade. |

1.4845 | X8CrNi25-21 | AISI 310S | High-temperature resistant grade. |

Japanese Industrial Standard (JIS) Grades

JIS Grade | Symbol | Similar U.S. Grade | Key Features |

SUS 304 | - | AISI 304 | General-purpose austenitic stainless steel. |

SUS 304L | - | AISI 304L | Low carbon version of SUS 304. |

SUS 316 | - | AISI 316 | Molybdenum-added for pitting resistance. |

SUS 316L | - | AISI 316L | Low carbon version of SUS 316. |

SUS 321 | - | AISI 321 | Titanium-stabilized grade. |

SUS 347 | - | AISI 347 | Niobium-stabilized grade. |

SUS 310S | - | AISI 310S | Heat and oxidation resistant grade. |

International Standards Compliance

BENKOO METAL seamless pipes are manufactured, tested, and certified to comply with a comprehensive range of international standards, ensuring global acceptance and performance reliability.

Product & Material Standards

Standard System | Standard Number | Title / Scope |

American (ASTM/ASME) | ASTM A213/A213M | Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes |

| ASTM A269/A269M | Seamless and Welded Austenitic Stainless Steel Tubing for General Service |

| ASTM A312/A312M | Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes |

| ASME SA213 / SA269 / SA312 | ASME Boiler and Pressure Vessel Code versions of ASTM standards. |

European (EN) | EN 10216-5 | Seamless steel tubes for pressure purposes – Part 5: Stainless steel tubes |

German (DIN) | DIN 17456 | Seamless circular stainless steel tubes – Technical delivery conditions |

Japanese (JIS) | JIS G3459 | Stainless steel pipes for ordinary piping |

| JIS G3463 | Stainless steel pipes for boiler and heat exchanger |

International (ISO) | ISO 1127 | Stainless steel tubes — Dimensions, tolerances and conventional masses per unit length |

| ISO 2037 | Stainless steel tubes for the food industry |

Supplementary & Testing Standards

Chemical Analysis: ASTM A484, EN 10088-1

Mechanical Testing: ASTM A370, ISO 6892-1

Hardness Testing: ASTM E10/E18, ISO 6506/6507/6508

Non-Destructive Testing (NDT): ASTM E213 (Ultrasonic), ASTM E426 (Eddy Current), EN 10246 series

Hydrostatic/Pressure Testing: ASTM A999, ISO 3458

Certification: EN 10204 3.1 / 3.2 Type Inspection Certificates

Applications of BENKOO METAL Austenitic Stainless Steel Pipes

Our seamless pipes are engineered for excellence in critical applications across multiple industries:

Industry Sector | Specific Applications | Recommended BENKOO METAL Grades |

Oil, Gas & Petrochemical | Process piping, heat exchanger tubes, refinery equipment, umbilicals, catalyst carrier tubes. | 316/316L, 317L, 904L, 6Mo Alloys (for severe chloride/acid service) |

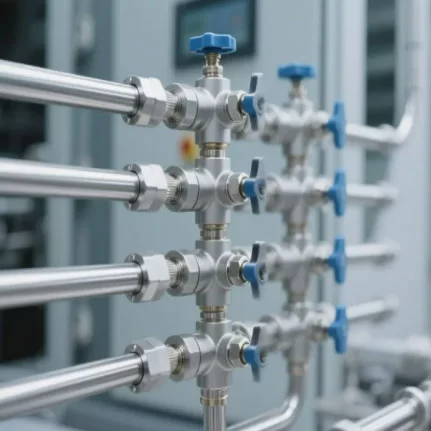

Chemical & Pharmaceutical | Reactor vessels, distillation columns, transfer lines, clean utility piping (WFI, CIP), fermentation tanks. | 304/304L, 316/316L, 904L, Electropolished 316L for high purity. |

Food & Beverage | Processing lines, pasteurizers, mixing tanks, brewing vessels, dairy piping, sanitary fittings. | 304/304L, 316/316L (for salt/vinegar), highly polished finishes. |

Power Generation | Boiler tubes, feedwater heaters, condenser tubes, cooling water systems (fresh & seawater), FGD systems. | 304/304H, 316/316H, 321, 347, 6Mo Alloys for aggressive cooling water. |

Pulp & Paper | Digester piping, bleach plant equipment, paper machine showers, black liquor recovery lines. | 316L, 317L, 904L, 6Mo Alloys. |

Marine & Offshore | Seawater cooling pipes, ballast systems, deck piping, desalination plant tubing, offshore platform fittings. | 316L, 6Mo Super Austenitics (254 SMO®), Duplex grades for strength. |

Architecture & Construction | Handrails, curtain wall supports, roof cladding, structural elements in coastal areas. | 304, 316 (for high chloride/saline atmospheres). |

Automotive & Aerospace | Exhaust systems, fuel lines, hydraulic tubing, aircraft ducting and engine components. | 304, 321, 347 (for high-temp exhaust parts). |

Why Choose BENKOO METAL?

Extensive Grade Portfolio: From standard 304/316 to premium super austenitic alloys.

Global Standards Expertise: In-depth knowledge and compliance with ASTM, JIS, DIN, EN, and other major standards.

Superior Quality Assurance: Rigorous testing protocols including PMI, NDT, and hydrostatic testing ensure defect-free products.

Technical Support: Our engineering team provides expert guidance on material selection, corrosion resistance, and application design.

Reliable Supply Chain: Consistent inventory and efficient logistics to meet project timelines globally.

Customer-Centric Approach: Dedicated to providing tailored solutions and building long-term partnerships.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

-20251217035818.webp)

-20251218091502.webp)