Material Grades & Specifications

We offer a complete portfolio of carbon and low-alloy steel grades to meet varying mechanical, pressure, and environmental requirements.

Comprehensive Material Grades & Standards for Welded Pipe

Material Category | Common Grades & Designations | Key Product Standards (Welded Pipe) | Primary Characteristics |

Standard Carbon Steel | ASTM A53 Gr.B (Type E, ERW), API 5L Gr.B (PSL1/PSL2) | ASTM A53, API 5L / ISO 3183 | General purpose, good strength & weldability. For mechanical, pressure, and structural use. |

High-Temp Carbon Steel | ASTM A106 Gr.B (Welded) | ASTM A106 (referenced for welded) | For high-temperature service in power plants and refineries. |

Structural Carbon Steel | DIN 1626 (St 37.0, St 44.0, St 52.0), EN 10219 S235-S460 | DIN 1626, EN 10219, ASTM A500 | Excellent cold forming properties, used for structural hollow sections in construction. |

Low-Temp Carbon Steel | ASTM A333 Gr.1, Gr.6 | ASTM A333 | Impact-tested for toughness at sub-zero temperatures. Ideal for cryogenic service. |

Chromium-Molybdenum Alloy Steel | ASTM A335 Gr.P6, Gr.P11, Gr.P22 | ASTM A335, ASTM A691 (for high-pressure welded) | Enhanced strength and creep resistance at elevated temperatures (up to ~650°C). P6 offers medium Cr content for improved oxidation resistance. |

High-Yield Strength Steel | API 5L X42 to X70, ASTM A671 / A672 (Plate Pipe) | API 5L, ASTM A671 / A672 | For high-pressure transmission pipelines and critical process lines requiring higher strength. |

Note: The aforementioned DIN 1026 standard pertains to tolerances on dimensions for steel tubes; the material specifications for structural tubes are typically governed by DIN 1626.

Applications by Industry

BENKOO METAL welded pipes serve as essential components across a broad industrial spectrum.

Key Industrial Applications & Material Selection

Industry Sector | Specific Applications | Recommended BENKOO METAL Grades | Why It Works |

Oil & Gas | Gathering/flow lines, utility piping, firewater lines, structural supports on platforms. | API 5L Gr.B / X grades, ASTM A53 Gr.B | Proven performance, cost-effective, meets industry-specific pressure and safety standards. |

Construction & Infrastructure | Structural columns, fencing, handrails, scaffolding, piling, building frames. | DIN 1626 St 37/52, ASTM A500 Gr.B/C, EN 10219 S355 | High strength-to-weight ratio, excellent for fabrication and welding into structural frameworks. |

Mechanical & General Engineering | Machine guards, conveyor frames, hydraulic system lines, agricultural equipment, rollers. | ASTM A53 Gr.B, DIN 1626 | Good machinability and weldability for custom fabrication of parts and frames. |

Power & Pressure Systems | Boiler feedwater lines, steam tracing, low-pressure steam, compressed air systems, heat exchanger shells. | ASTM A53 Gr.B, ASTM A335 P-Series (e.g., P6, P11) for high-temp | Reliable pressure containment; alloy grades withstand elevated temperatures without significant loss of strength. |

Water Transmission & Utilities | Potable water mains, irrigation systems, drainage, sewage treatment plant piping. | API 5L Gr.B, ASTM A53 Gr.B, EN 10224 | Durable, cost-effective solution for long-distance fluid transport and municipal networks. |

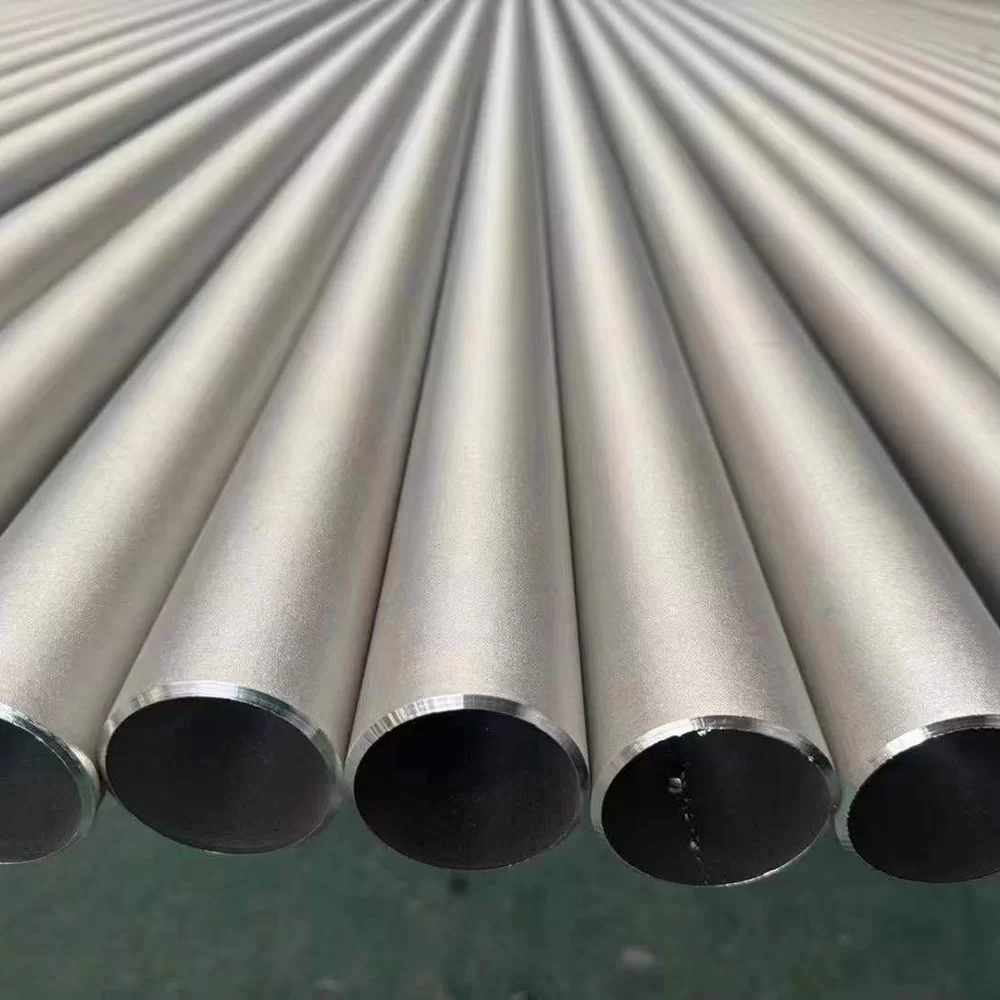

Product Specifications

BENKOO METAL welded pipes are available in a wide range of sizes and manufacturing specifications.

Standard Product Specifications

Parameter | Specifications | Details |

Manufacturing Process | Electric Resistance Welding (ERW), Longitudinal/Helical Submerged Arc Welding (SAW/LSAW) from plate. | ERW for standard sizes; SAW/LSAW for larger diameters and heavier walls. |

Size Range (OD) | 1/2" Nominal Bore (21.3mm OD) to 100" (2540mm OD) and larger. | Vast range to suit everything from small-bore utilities to major transmission lines. |

Wall Thickness | Schedules: SCH 10, 20, STD, 40, 80, XS, XXS. Custom thickness available per ASTM/ASME B36.10. | Designed to meet specified pressure ratings and mechanical loads. |

Length | Random (RAND) lengths: typically 18-24 ft (5.5-7.3m), or cut to precise length (CTL). |

|

End Finish | Plain end, Beveled for welding, Threaded & Coupled (T&C). | Prepared as per installation requirements. |

Protective Coating | Bare (mill scale), Black, Galvanized (ASTM A53), FBE, 3LPE/3LPP coatings available. | For corrosion protection based on service environment. |

Industrial Products Made from Carbon Steel Welded Pipe

Carbon steel welded pipe is a versatile feedstock for fabrication. It is primarily used to construct: structural frameworks and building frames, handrails and safety barriers, industrial scaffolding, conveyor system structures, fluid transport lines (water, oil, gas, air), casing for concrete piles, protective fencing, and support legs for machinery and equipment. Its combination of strength, ease of fabrication, and economy makes it the default choice for countless fabricated industrial products and systems.

Why Choose BENKOO METAL?

Full Material Spectrum: From basic carbon steel to specialized alloy grades.

Standards Compliance: Certified to ASTM, API, DIN, EN, and other project-specific standards.

Quality Assurance: Rigorous testing including hydrostatic, NDT (UT/ET), and dimensional inspection.

Technical Support: Assistance in selecting the optimal grade and specification for your application and budget.

Global Supply Reliability: Consistent quality and on-time delivery to support project timelines anywhere.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

-20251219074922.webp)

-20251219074940.webp)

-20251217035818.webp)

-20251219064452.webp)