Detailed Technical & Application Overview

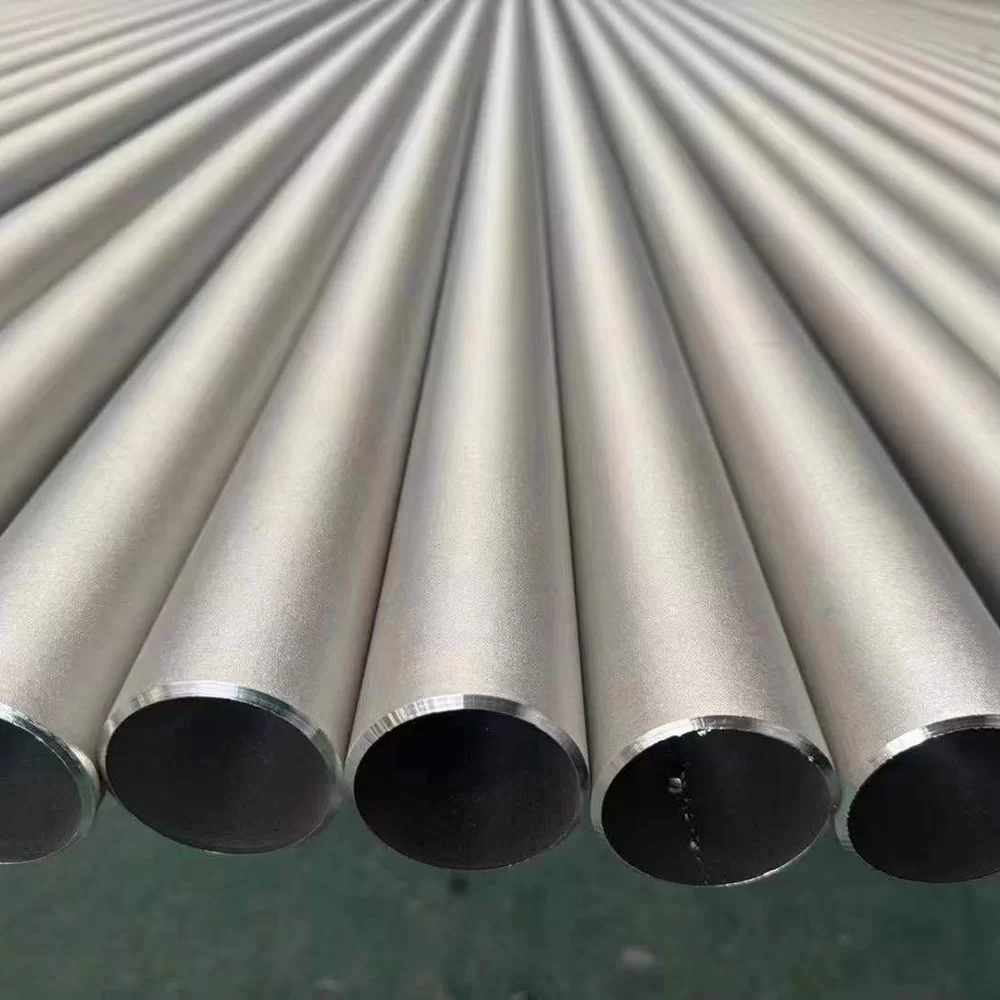

When operational conditions push beyond the limits of conventional materials—encountering concentrated acids, extreme heat, or pervasive chlorides—the selection of piping material becomes the single most critical factor for safety, integrity, and economic viability. BENKOO METAL specializes in welded pipes made from nickel-chromium-molybdenum (Ni-Cr-Mo) and other nickel-based alloys, which represent the pinnacle of corrosion-resistant alloy (CRA) technology.

These alloys derive their exceptional properties from high nickel content, which provides inherent ductility and resistance to stress corrosion cracking, combined with strategic additions of chromium (for oxidation resistance), molybdenum (for resistance to reducing acids and pitting), and other elements like copper or tungsten. BENKOO METAL utilizes specialized welding and post-weld heat treatment techniques to preserve these alloys' microstructural integrity, delivering a finished product capable of enduring decades of service in aggressive and high-stress applications, from subsea pipelines to chemical reactor effluents.

-20251219073612.webp)

Critical Applications in Demanding Industries

The following table details the specific challenges and solutions where BENKOO METAL nickel alloy welded pipes are indispensable.

Industry Sector | Critical Applications | Primary Material Challenge | BENKOO METAL Solution & Benefit |

Oil & Gas (Upstream/Sour Service) | Downhole tubing, Wet gas gathering lines, Seawater injection lines, Components in H₂S/CO₂ (sour) environments. | Chloride Stress Corrosion Cracking (SCC), general and pitting corrosion from produced fluids and seawater, sulfide stress cracking. | Alloys like UNS N08825 and UNS N06625 offer proven resistance to sour service and chloride SCC, replacing costly failures and ensuring well integrity. |

Chemical & Petrochemical Processing | Reactors, columns, and piping for sulfuric, hydrochloric, and phosphoric acid service; Heat exchangers for aggressive media. | Attack from hot, concentrated mineral acids, oxidizing and reducing salt environments. | Hastelloy®-type alloys (e.g., UNS N10276, N06022) provide unmatched resistance to a vast range of acids and chlorides, maximizing plant on-stream time. |

Power & Flue Gas Cleaning | Fine Gas Desulfurization (FGD) system components (e.g., absorber internals, outlet ducting), Advanced Ultra-Supercritical (A-USC) boiler tubing. | Condensation of hot, acidic chlorides and sulfates in scrubbers; High-temperature oxidation and creep in boilers. | High-Molybdenum alloys (e.g., UNS N10276) for FGD wet zones; High-temperature alloys (e.g., UNS N06617) for advanced boiler sections. |

Marine, Offshore & Desalination | Seawater cooling piping, High-pressure Reverse Osmosis (RO) membranes and brine lines, Offshore platform critical process piping. | Severe pitting and crevice corrosion in chlorinated seawater; Erosion-corrosion in high-velocity flows. | Alloys like UNS N05500 (Monel® K-500) and UNS N06625 provide longevity in seawater systems far exceeding stainless steels. |

Material Grades & International Standard Compliance

BENKOO METAL supplies a comprehensive portfolio of nickel alloy grades, each certified to stringent international specifications for welded pipe.

Key Nickel Alloy Grades & Specifications

Common Trade Name | UNS Number | EN / DIN Material Number | Key Characteristics & Primary Use |

Alloy 825 / Incoloy® 825 | N08825 | 2.4858 (NiCr21Mo) | Excellent resistance to reducing acids (H₂SO₄) and oxidizing salts. Standard for sour service oil & gas applications. |

Alloy 625 / Inconel® 625 | N06625 | 2.4856 (NiCr22Mo9Nb) | Outstanding fatigue strength and resistance to pitting, crevice corrosion, and high-temperature oxidation. Versatile for marine, aerospace, and chemical. |

Hastelloy® C-276 | N10276 | 2.4819 (NiMo16Cr15W) | The benchmark for severe chemical service. Exceptional resistance to hot chloride solutions, wet chlorine, and mixed acids. |

Hastelloy® C-22® | N06022 | - | Enhanced corrosion resistance over C-276 in highly oxidizing and mixed acid/chloride environments. |

Monel® 400 | N04400 | 2.4360 (NiCu30Fe) | Superior resistance to seawater, hydrofluoric acid, and alkaline solutions. Classic material for marine engineering. |

Alloy 20 (Carpenter 20®) | N08020 | - | Excellent resistance to sulfuric acid and chloride stress corrosion cracking. Common in chemical and pharmaceutical. |

Inconel® 617 | N06617 | 2.4663 | A solid-solution strengthened alloy with exceptional high-temperature strength and oxidation resistance up to 1100°C. For A-USC power plants. |

Governing International Product Standards

Region/System | Standard Number | Title / Scope |

American (ASTM/ASME) | ASTM B775 / B829 | General Specification for Nickel Alloy Welded Pipe / General Requirements. |

| ASTM B704 / B705 | Standard Specification for Welded UNS N06625, N08825, and N10276 Pipe. |

| ASME SB-XXX | Boiler and Pressure Vessel Code equivalents. |

European (EN) | EN 10217-7 (Referenced) | Welded steel tubes for pressure purposes – Stainless steel tubes (Nickel alloys may be supplied to chemical comp. specs). |

German (DIN) | DIN 17750 | Seamless and welded circular tubes of nickel and nickel alloys – Technical delivery conditions. |

Japanese (JIS) | JIS H4552 | Welded Nickel and Nickel-Alloy Pipes. |

Product Specifications & Comprehensive Size Range

BENKOO METAL offers unmatched versatility in nickel alloy welded pipe dimensions, catering to both precision instrument lines and large-scale industrial projects.

Specification | BENKOO METAL Offering | Technical & Quality Notes |

Outside Diameter (OD) | 6 mm to 3000 mm | Full Portfolio Coverage: From capillary and instrument tubing (6mm) to large-diameter process lines, scrubber ducting, and seawater intake pipes (3000mm). |

Wall Thickness | 1.0 mm up to 50+ mm (schedule or custom) | Designed to meet ASME B31.3 / EN 13480 pressure design requirements. Thickness optimized for corrosion allowance and mechanical loads. |

Manufacturing Process | Automatic TIG, Plasma, or Longitudinal SAW from certified plates/coils. | Welding under inert gas protection. All welds are 100% radiographically inspected. Solution annealing and pickling are performed to restore optimum corrosion resistance. |

Certification & Testing | EN 10204 3.2 Type Certificate standard. | Includes full melt traceability, mechanical testing, chemical analysis (PMI verification), and non-destructive testing (RT/UT). NACE MR0175/ISO 15156 certification for sour service is available and often standard. |

The BENKOO METAL Advantage: Expertise in Extreme Alloys

Choosing BENKOO METAL for nickel alloy welded pipes secures a partnership with true specialists:

Application Engineering: We help select the most cost-effective alloy for your specific process environment, avoiding both under- and over-engineering.

Weld Procedure Expertise: Nickel alloys require precise welding controls. We provide support with procedure qualification to ensure fabrication success.

Global Supply with Integrity: Complete traceability and certification packages that meet the scrutiny of international energy and engineering majors.

Commitment to Performance: We guarantee that our products meet the published specifications for corrosion resistance and mechanical properties.

For Projects Where Material Performance is Paramount.

Contact BENKOO METAL for expert consultation, detailed technical data sheets, and a quotation tailored to your project's unique challenges in corrosive or high-temperature service.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

-20251219071741.webp)

-20251219071755.webp)

-20251219063146.webp)

-20251217035818.webp)

-20251218091502.webp)